I work for Mycorena, a biotechnology company that grows fungus-based vegan protein. We launched in 2017 and are based in Gothenburg, Sweden. The mycoprotein we grow can be used to manufacture a variety of products, from vegan leather to animal feed and meat substitutes. Our food product, Promyc, is already available in Swedish shops and restaurants, and we are collaborating with companies that will sell it elsewhere in the European Union.

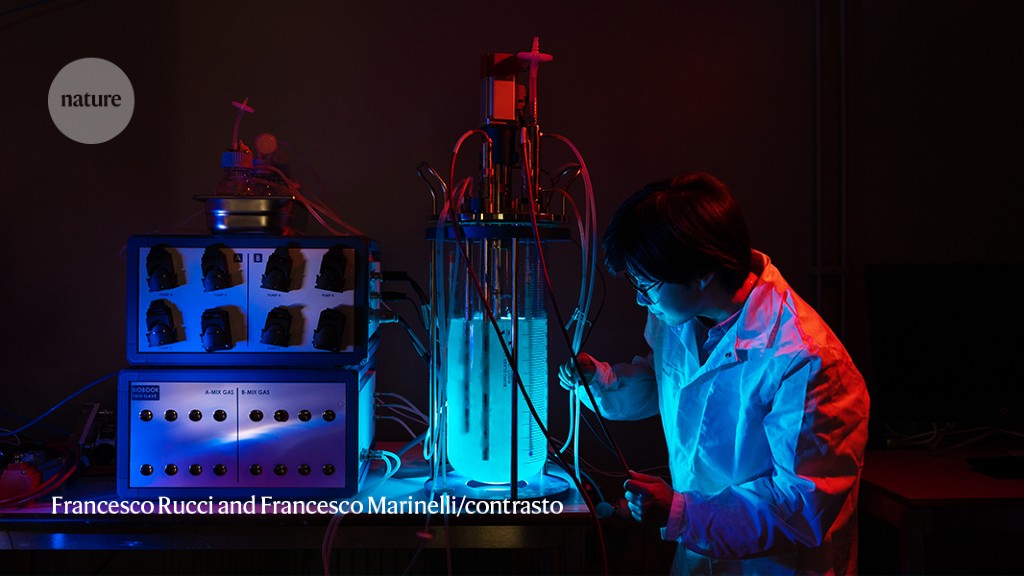

As a fermentation scientist, I develop and optimize the company’s procedures for growing mycoprotein in big vats called bioreactors. In this picture, I’m studying a desktop version of the process. I can vary the bioreactor’s parameters by using different nutrients, changing the stirring speed to regulate the airflow or adjusting the pH, for example.

Our product looks nothing like the mushrooms in a forest. We grow mycelium, the microscopic filaments from which such mushrooms grow. The mycelium is fibrous, like animal muscles, and its neutral taste means that you can add any flavour you like. Food protein grown in this way produces fewer carbon emissions than does conventional meat production, while still providing abundant nutrients.

I have studied fungi for many years. I earned my PhD at the University of Copenhagen last year, studying how different microorganisms interact. Fungi are amazing. With some microbes, such as bacteria, strains are similar within the species. But fungi of the same species can have completely different behaviours and it’s not always known why.

We are constructing our first commercial factory in Falkenberg, Sweden, and want to make fungus-fermentation technology more widely available, to help the food industry become more sustainable and diverse. And we want to bring mycoprotein to other areas of the food industry — for example, 3D food printing. There will be a lot of challenges, but that is our goal.

More News

Author Correction: Stepwise activation of a metabotropic glutamate receptor – Nature

Changing rainforest to plantations shifts tropical food webs

Streamlined skull helps foxes take a nosedive