Would you eat a burger enriched with mealworms? Fake bacon sliced from a mass of fermented fungi? Milk proteins extruded by microbes? Maybe you already have. Dozens of companies are now banking on these alternatives to animal protein becoming a regular part of your diet.

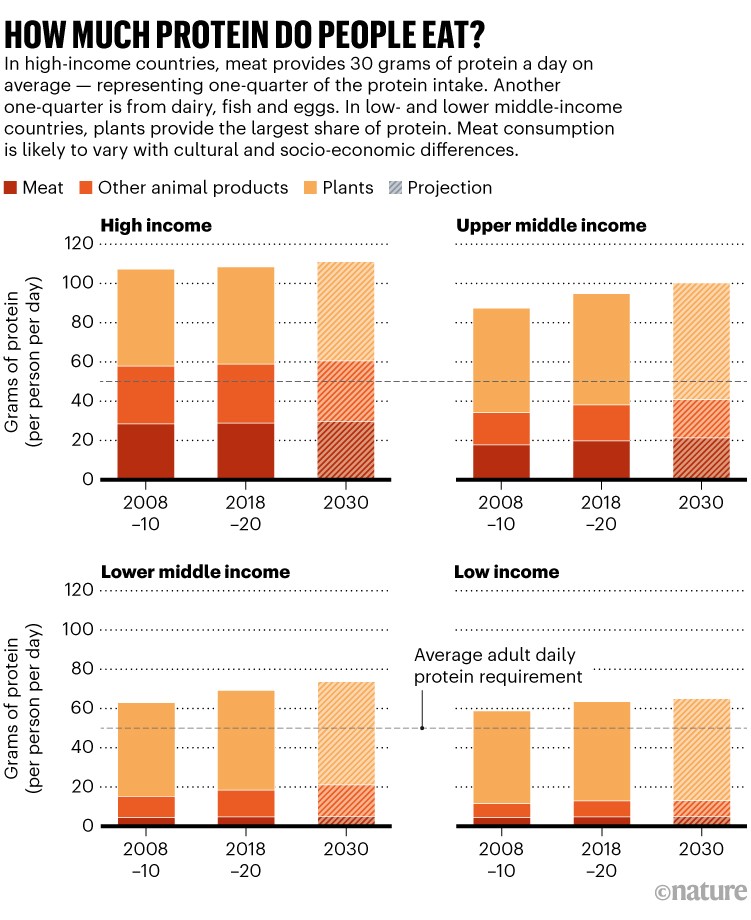

Human diets do not, on average, lack protein, says Marco Springmann, a food-systems researcher at the London School of Hygiene & Tropical Medicine; in fact, most people currently eat more than enough. On average, people require about 50 grams of protein per day. But in wealthy regions such as North America and Europe, people typically consume about twice that amount (see ‘How much protein do people eat?’).

Source: C. Frezal et al. https://doi.org/kgpt (OECD, 2022); US FDA https://go.nature.com/3R7HPBY (daily protein).

The problem these companies are trying to solve is where that protein comes from. In wealthy nations, about half of the consumed protein comes from animal products. The average American eats more than 120 kilograms of meat per year.

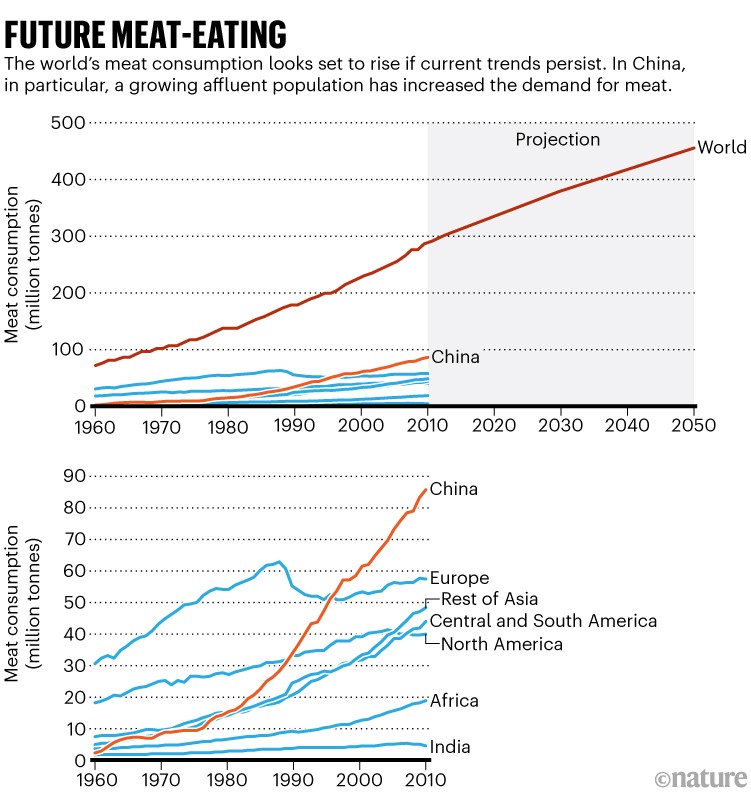

In general, as wealth rises, the demand for meat rises, too — a trend that is particularly noticeable in China, where the amount of meat eaten has exploded about 15-fold since 1960(see ‘Future meat-eating’).

Source: Ref. 9.

Eating so much meat puts pressure on animals, people and the planet. A 2019 report by the EAT Lancet Commission1 concluded that a sustainable global diet that is healthy for both people and the planet would require slashing the amount of red meat produced, including pork and beef, by around 75%. At the same time, production of vegetables, fruit, beans and nuts would need to at least double.

Meat isn’t all bad: it is packed with essential amino acids and nutrients, and livestock plays an important part in many ecosystems and societies. But replacing red meat in particular could make a huge difference for both people and the planet. One study found that replacing 20% of global ruminant meat (such as beef) with microbial protein alternatives by 2050 could roughly halve annual deforestation2.

Alternatives to animal protein aren’t hard to find. Plants — such as peas, beans, grains and nuts — are a cheap and ubiquitous protein source that have a long track record for maintaining human health and a low carbon emissions footprint. “The clear winner is minimally processed plant-based sources of protein. In any assessment, they win hands down,” says Springmann. Then there are conventional plant-based products, such as tofu (from soya milk), seitan (from wheat) and tempeh (from fermented soya).

Lab-grown meat: the science of turning cells into steaks and nuggets

In the past few decades, there has been an explosion of plant-based meat imitators from companies including Impossible Foods, Beyond Meat, Gardein and more. Most are still niche products. The Good Food Institute, a non-profit organization based in Washington DC, reports that sales of plant-based alternatives to meat and fish totalled US$6.1 billion in 2022. That is an 8% increase from 2021, it notes, but still a tiny proportion of the multitrillion-dollar market for animal products.

Now the market is widening to encompass all kinds of alternatives, from insects to microbes. These proteins could have an important role in making food more efficient and environmentally friendly for both humans and animals. Researchers and manufacturers are joining the hunt for the protein of the future, all hoping to overcome the challenge of cost — and the whims of taste.

Cultured meat

Meat can now be grown in a laboratory rather than obtained from slaughter. Researchers and companies are focusing on finding the best cell lines to use as starters, improving methods for growing cells in bioreactors and perfecting taste and texture — all while finding ways to lower costs. The United States gave the green light to its first two cultured-meat products in June. The energy demand of cultured meat is extremely high, but land and water use for its production are extremely low. Overall, the carbon footprint of cultured meat, assuming it is produced using renewable energy, could be about the same as or less than that of poultry, and one-tenth that of beef cattle3. Reduced antibiotic use in cultured products could reduce global antibiotic-resistance issues.

Plant-based meat substitutes

Soya has been the early leader in plant-based alternative protein products (including burgers made by Impossible Foods based in Redwood City, California), but pea proteins are rising fast, in part because of public concerns about allergens and hormones (soya contains isoflavones, a type of plant oestrogen that weakly mimics the human form). Many plant-based products such as sausages are, like their meat equivalents, highly processed to help to create the desired texture and taste, and can include additives such as salt, sugar, colour, flavour enhancers and masking agents to hide, for example, ‘beany’ off-flavours in pea protein — all of which can affect nutrition4. A few researchers and companies are focused on tailoring crops such as pea or sorghum for plant-based meat — for example, by increasing their protein content or reducing the requirement for taste-improving additives.

Recombinant proteins

Genetically modified (GM) bacteria and yeast are used to create a variety of useful proteins through ‘precision fermentation’. In cheesemaking for example, rennet, a mix of enzymes traditionally harvested from calves’ stomachs that sets the cheese, is now predominantly replaced by chymosin churned out by GM microbes. This is the case even in much of the European Union, where GM technology faces high regulatory hurdles and where many other proteins produced using genetic modification have yet to receive approval.

The company Perfect Day in Berkeley, California, uses a fungus, Trichoderma reesei, which has been genetically programmed to make β-lactoglobulin (cow whey protein) for its animal-free milk products, including Brave Robot ice cream in the United States and Very Dairy milk in Asia. Impossible Foods uses GM Pichia pastoris yeast to pump out soya leghaemoglobin, a blood haem alternative used for colour and flavour in its fake burger. The company, which sells products internationally, has applied to the European Food Safety Authority for approval of its flagship burger. Various companies are using GM microbes to make milk casein proteins, egg-white proteins, muscle myoglobin and even proteins from human breast milk, alongside many of the growth factors needed in cultured-meat production.

Research is focused on finding the most efficient, cheapest ways of producing pure end products that have desirable qualities (including shelf life, melt temperature or chewiness). This year, a handful of food technology start-up firms founded the Precision Fermentation Alliance to promote the concept.

Mycoproteins

Fermenting filamentous fungi in a lab can produce a high-fibre, high-protein food with a texture similar to that of lean chicken. A version made from Fusarium venenatum (found originally in 1967 in an English garden) entered the market in the United Kingdom in the 1980s and in the United States in the early 2000s. It is sold as Quorn.

Other fungi can also provide mycoprotein: the company Nature’s Fynd in Chicago, Illinois, for example, uses Fusarium strain flavolapis, a fungus found originally in Yellowstone Park in Wyoming, to make meatless patties and a cream-cheese alternative. There are at least a dozen companies aiming to develop mycoprotein products, including multinational giant Unilever, which uses a mycoprotein called Abunda in its Vegetarian Butcher product line. Others are making fungi-based fish and bacon alternatives.

Fungi need to be fed sugar to grow mycoprotein, which is then heated to denature the RNA to make it safe to eat. Some products use a small amount of egg as a binder. Researchers are tweaking the process to find products with the most desirable nutrition, taste and texture at the lowest cost. That might involve, for example, feeding the fungi cheap agricultural waste products such as spent grain from brewing5.

Algae

Macroalgae, including seaweeds, are a common high-protein food ingredient in some cultures. There’s an increasing interest in farming kelp to help ecosystems; to sequester carbon; and to provide protein for people and animals. Studies have suggested that red-algae supplements, in particular, could slash methane burps from cattle by more than 80%, with benefits for climate change6. Start-up firms, including Rumin8 in Perth, Australia, are investigating this idea. Microalgae such as spirulina are also used in protein powders and in alternative products such as algae-based flour.

Researchers have suggested harnessing the powers of artificial intelligence and computer modelling to find the best, highest-efficiency strains of microalgae — and to tone down their green colour and fishy taste7.

Bacterial proteins

Some bacteria produce protein naturally from carbon dioxide in the air if they are also fed with hydrogen gas. Making hydrogen takes a lot of energy, however, typically by splitting water.

Finland’s Solar Foods uses a natural strain of Xanthobacter, for example, to make a protein powder for human consumption called Solein, which was approved in Singapore last year; the firm has also applied for approval from the European Food Safety Authority.

Bacterial protein is already used in animal feed — Calysta in San Mateo, California, for example, uses methane-munching bacteria to produce FeedKind, a protein that they turn into fish food and a supplement for pigs.

Insects

Many cultures around the world eat insects, often whole and roasted as snacks. In recent years, companies have geared up to farm them — mainly for animal feed or as pet food. Factories churn out crickets and grasshoppers, black-soldier-fly larvae and mealworms; Europe, a hotspot of insect farming, produces 6,000 tonnes of insect protein each year8. Bug-based burgers have been available there for many years; the EU approved whole, dried yellow mealworms (Tenebrio molitor) as a human food in May 2021. Flours made from locusts or crickets are widely available internationally.

Although insects seem like an easy thing to farm, protein powders made from them are surprisingly expensive, mainly thanks to the energy and labour costs and the inefficiencies of small-scale production. According to a 2019 World Economic Forum white paper9 on alternative proteins, the cost of insect protein to consumers was about two-thirds that of cultured meat — much pricier than algae, chicken or tofu, not to mention even cheaper conventional beef, nuts and plants. And insects are still animals, with associated welfare issues.

For people and planet

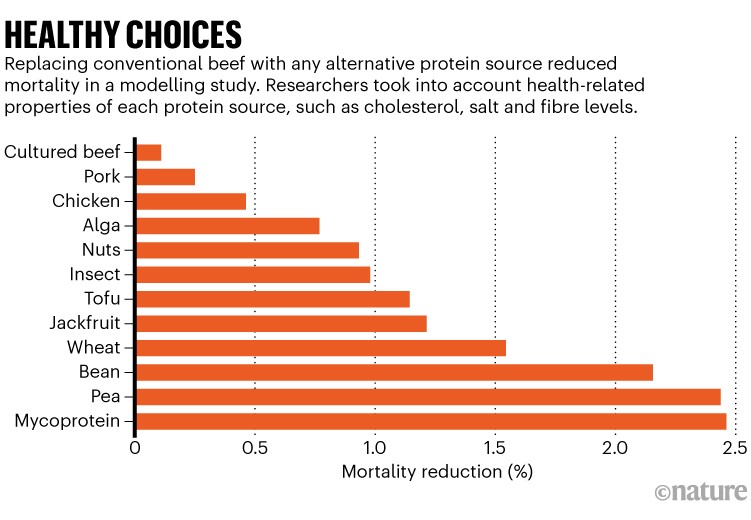

Almost all alternative, non-meat proteins are healthier than red meat. When researchers analysed ways in which different protein sources affected health9 — looking at cholesterol, salt, fibre, fat and more — they found that meat was the most damaging. Pork and beef contributed the most to diet-linked deaths, and this would remain the case for cultured versions. Protein from fungi and peas was the healthiest choice in the list, reducing mortality rates by almost 2.5% (see ‘Healthy choices’).

Source: Ref. 9.

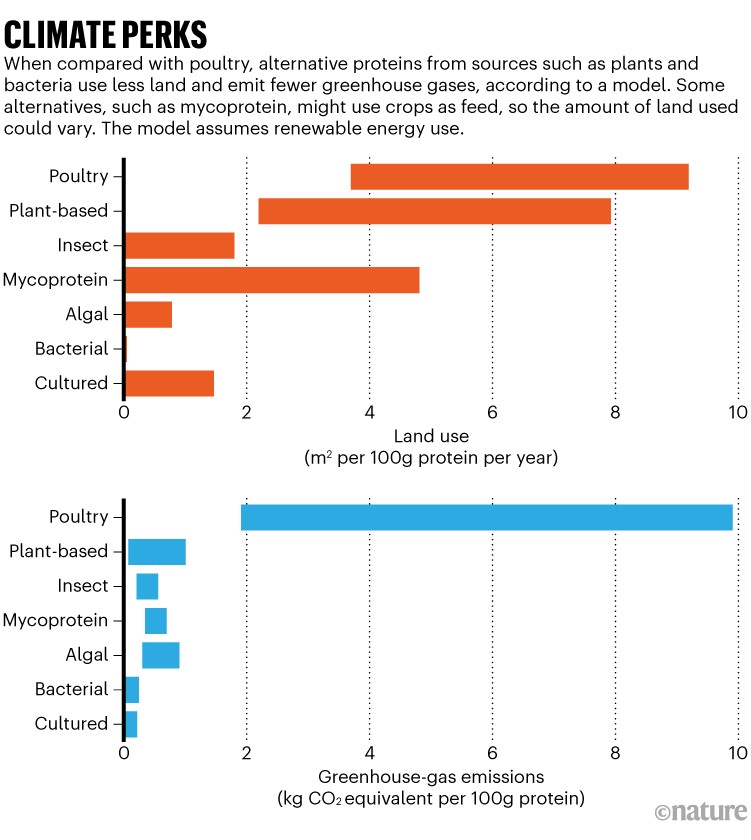

In general, all meat alternatives will lighten the burden on the planet — as long as the energy used is renewable and the foods replace conventional meat.

A 2021 report by researchers at the University of Oxford10 found that the global food system releases about 14 gigatonnes of greenhouse gases, accounting for about one-quarter of total emissions. Of that 14 gigatonnes, about 40% comes from plant-based foods and 60% from meat (including crops grown to feed livestock). So swapping out all meat for any alternative protein created with renewable energy, the report concludes, would effectively halve food emissions. By the same logic, replacing 10–20% of global meat consumption with alternatives could save about one gigatonne of greenhouse-gas emissions — more than is spewed out every year by the aviation industry.

Some alternatives are better than others. Bacterial proteins do well in terms of minimal land use and greenhouse-gas emissions, for example, whereas plant-based foods take up a lot of land but have a small carbon footprint (see ‘Climate perks’).

Source: Ref. 10.

Various alternatives could fill specific niches in the market, says Good Food Institute molecular biologist Adam Leman in Chapel Hill, North Carolina. Where renewable electricity is cheap, fast-growing bacteria are a good option for churning out a protein powder; where there is agricultural waste, fungi can use it to make a textured mycoprotein nugget. “We’re going to need all of them,” he says.

More News

Quantum control of a cat qubit with bit-flip times exceeding ten seconds – Nature

Venus water loss is dominated by HCO+ dissociative recombination – Nature

Microbubble ultrasound maps hidden signs of heart disease