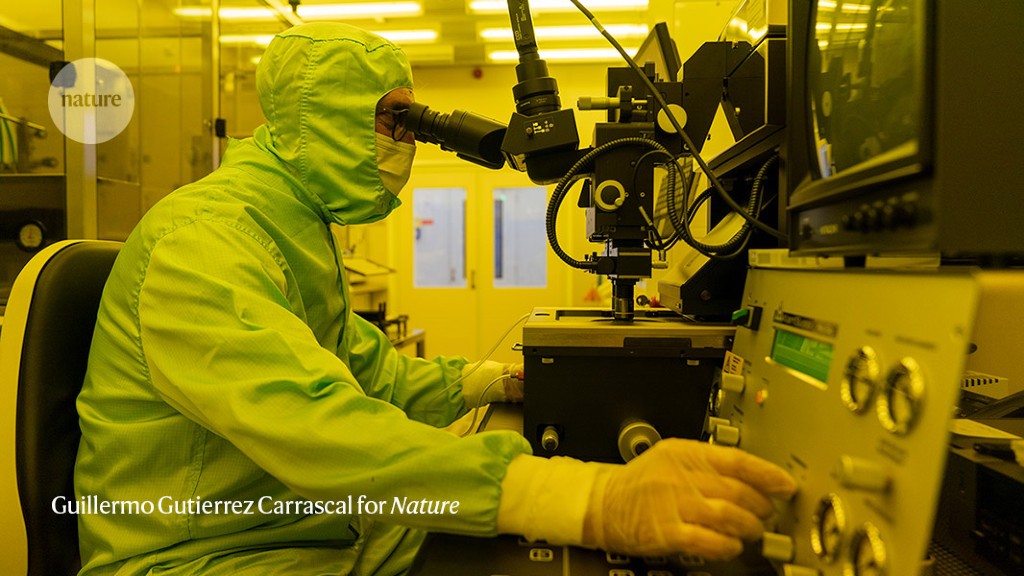

The Institute of Microelectronics of Barcelona, in Spain, where we research and develop micro- and nanotechnology, hosts the largest ‘clean room’ in southern Europe, at 1,500 square metres. A clean room is a controlled environment where pollutants such as dust, airborne microorganisms and aerosol particles are filtered out.

The picture above was taken in the clean room’s photolithographic laboratory. This is where we transform silicon wafers into micro-, nano- or photonic chips. We use yellow light in here because the fabrication process is sensitive to the ultraviolet light in standard lighting.

The air in this part of the clean room is 10,000 times cleaner than ‘normal’ air. The air filters block any particle that could interfere with the fabrication. They also change all of the air in the room about once a minute.

We wear protective suits like the one I have on in the picture to protect the chips; unwanted particles could make them defective.

Here, I’m looking through the microscope of a contact-alignment instrument. This ensures the correct alignment of the layers of silicon dioxide and other metals that are deposited on the wafers as part of our chip-manufacturing process.

Including technicians and engineers, the clean room has a team of around 40 people. We research how our technologies can be applied in many different fields: health, the environment, energy and space exploration.

We have developed a way to make chips tiny enough to enter living cells. These nanostructures allow scientists to identify and track living cells and to understand how these cells work from within.

The tiny chips can also be used as nanotools to keep cancer cells from developing. In this way, we hope to find alternatives to chemotherapy and other treatments that are too aggressive for the human body.

More News

Star Formation Shut Down by Multiphase Gas Outflow in a Galaxy at a Redshift of 2.45 – Nature

Garden-variety fungus is an expert at environmental clean-ups

Air-travel climate-change emissions detailed for nearly 200 nations